ELECTRICAL

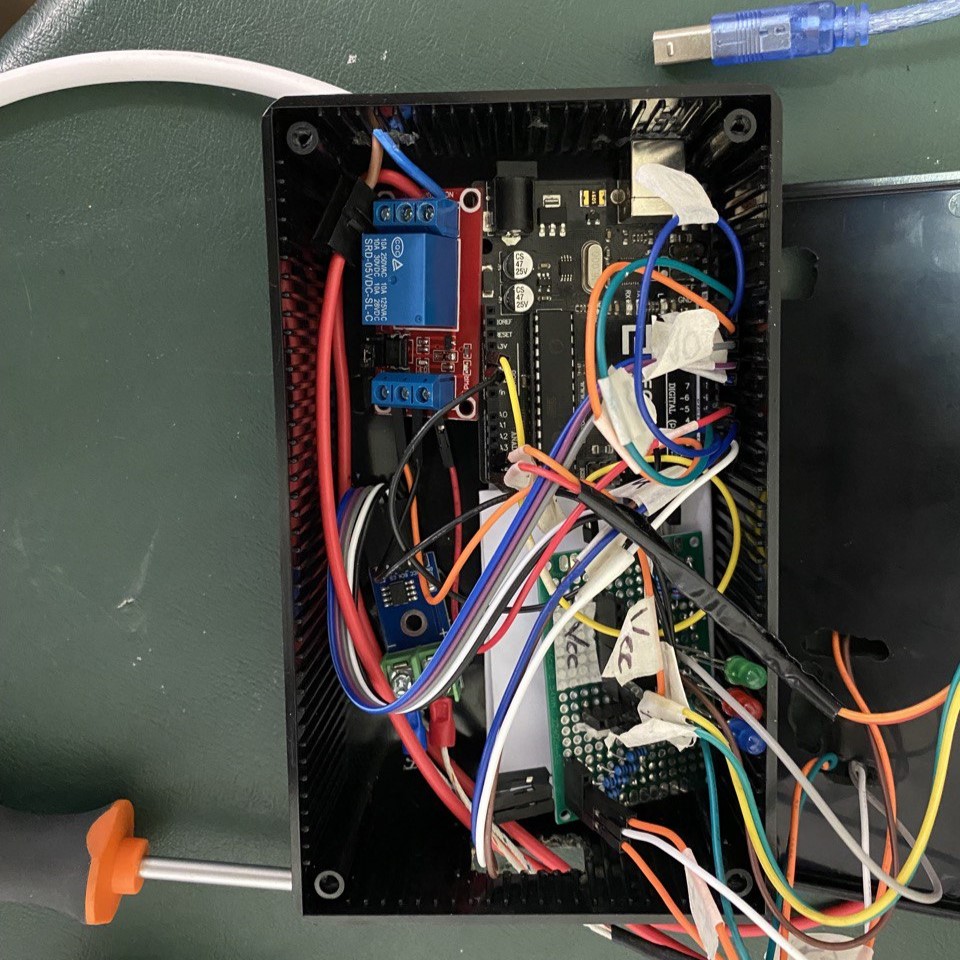

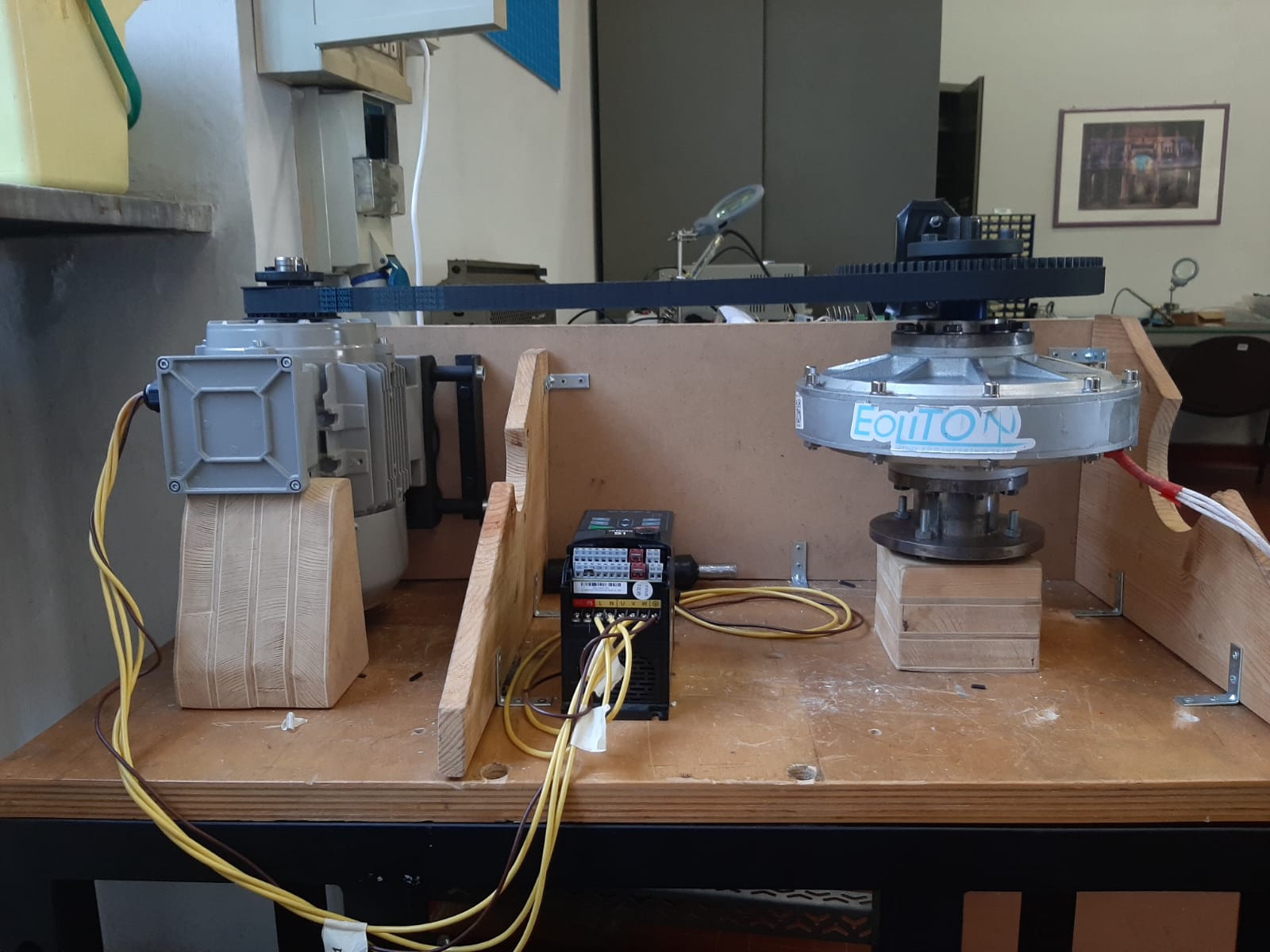

The electrical group develop and build all the devices that form the “conversion system”, starting from the generator and finishing with a Li battery pack. In particular we build the inverter unit, a device that manage the conversion between the three-fase output of the generator and the DC voltage of the battery pack. The electronic engineers of the team write the firmware for the MCU that controls the power flow through the boar.